All About Glycol

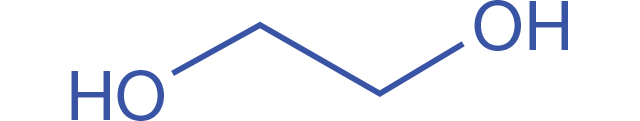

You may know KOST® USA for our antifreeze/coolant, but we specialize in a range of high-quality glycol-based products. We use virgin, ASTM E1177 glycols to produce a wide range of products. Let’s see how KOST® USA utilizes each glycol’s unique characteristics to produce high-quality products. Glycol is the chemical “anti-freeze” component in antifreeze/coolant. Glycol is the common name for a category of chemicals containing two hydroxyl groups (-OH) connected to two different carbon atoms (see figure 1)

Figure 1: Molecular structure of ethylene glycol, a glycol commonly used in antifreeze. Each change of angle in the black line represents a carbon atom.

Since glycols’ different structures lend the chemicals a range of properties, certain glycols are suitable for specific applications. KOST® uses several different glycols for our products, including ethylene glycol (EG), propylene glycol(PG), diethylene glycol (DEG), and triethylene glycol (TEG).

Ethylene Glycol

Ethylene Glycol (EG, pictured in Figure 1) is most commonly used in automotive and heavy-duty antifreeze/coolant. Its low freeze point (-34˚F in 50/50 antifreeze) and high boiling point (265˚F in 50/50 antifreeze with a properly functioning pressure cap) allow for it to be used in internal combustion engines in most climates year-round. It is cost-effective and resistant to oxidation (essential for protecting your engine against corrosion), but highly toxic, so it should not be used in systems where accidental ingestion is a possibility. KOST®USA uses ethylene glycol in our DefendAL® antifreeze/coolant lineup (www.kostusa.com/page/defendal), where we offer a range of technologies to suit your needs.

Propylene Glycol

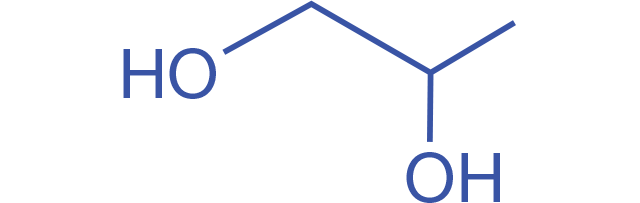

Propylene Glycol (PG, pictured in Figure 2) is most commonly used in heat transfer fluids. However, it is also used for antifreeze/coolant in applications where accidental spillage or ingestion might be a concern (such as RV and Marine antifreeze). Notice that it has three carbon atoms to the two carbon atoms in EG: this difference in structure gives it a different freeze point (-28˚F in 50/50 dilution) boiling point (222˚F in 50/50 dilution with a properly functioning pressure cap), and lower toxicity. PG’s lower toxicity allows for it to be used as Heat Transfer Fluid (HTF) in a broader range of applications, such as HVAC systems, process heating and cooling, and boiler systems. Any process in which accidental ingestion might be a concern typically uses PG instead of EG.

KOST® USA uses both EG and PG in our KOSTChill® HTF lineup (www.kostusa.com/page/kostchill), which is available in a range of technologies and dilutions.

Figure 2: Molecular structure of propylene glycol.

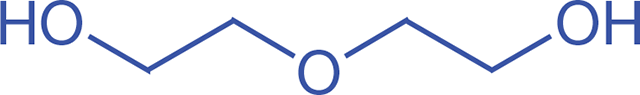

Diethylene Glycol – Two ethylene glycols combined

KOST® USA uses Diethylene Glycol (DEG, pictured in Figure 3) in our FM Approved Fire-Resistant Hydraulic Fluid (FRH). DEG is cost-effective, miscible with water, lubricious, and enables low temperature pumpability, which makes it ideal for use in water-glycol (HFC) FRH. FRH is commonly used in hydraulic equipment found in die-casting, steel mills, and mining. KOST® USA offers our AchievAL® FRH (www.kostusa.com/page/achieval) in concentrate and ready-to-use to suit your needs.

Figure 3: Molecular structure of diethylene glycol

Triethylene Glycol – Three ethylene glycols combined

Triethylene Glycol (TEG, pictured in Figure 4) is useful for its hydrophilic, or water-loving, properties as well as its relatively high boiling point. These characteristics make it ideal for use in Gas Dehydration Fluid. This fluid is used in the natural gas industry to remove water from natural gas after it is pumped out of the ground. This “wet” gas is bubbled through the TEG-based gas dehydration fluid, where the TEG absorbs the water. The now “wet” TEG is cycled through a boiler to boil off the water and return the fluid to a “dry” state where it can then be reused. TEG’s boiling point of 545 ˚F makes it ideal for this application since the high boiling point allows the water (with a boiling point of 212 ˚F) to be boiled off without losing TEG! KOST® USA’s KOSTherm® HD TEG (www.kostusa.com/page/kostherm) contains both TEG and inhibitors to operate in most dehydration systems, protect metals in the dehydration system, and extends the life of the fluid.

Figure 4: Molecular structure of triethylene glycol.

Visit our website at kostusa.com or contact your sales representative to learn more about our product lineup!

Sticking With Green

If you have been maintaining vehicles for decades, it is easy to stick with what you know when it comes to cooling system fluids: conventional “green” antifreeze. The maintenance practices are easy to remember: replace every 12 months or 12,000 miles. But the old standard green isn’t the best coolant for modern engines, and misusing it can even cause damage! Here are three things to consider if you are still using conventional technology antifreeze:

- If you are using it in a vehicle with the model year 1996 or newer, you are likely using sub-optimal antifreeze for your system: most automotive makes of these model years use organic acid technology (OAT) antifreeze due to the high aluminum content of their cooling systems.

- Sticking with conventional technology antifreeze can be more costly: the increased maintenance compared to OAT antifreeze/ coolant can cost time and money.

- Using conventional “green” antifreeze/coolant in heavy duty applications can cause catastrophic damage in the form of liner pitting/cavitation. Review manufacturer recommendations: you typically need to add an SCA to green antifreeze to use it in heavy duty applications.

KOST® USA still offers conventional green (DefendAL® Universal) antifreeze for use in older vehicles, but there is likely a better choice for your application for model years 1996 and newer. See our lineup or ask for technical support at kostusa.com.